-

The seal from my record player

-

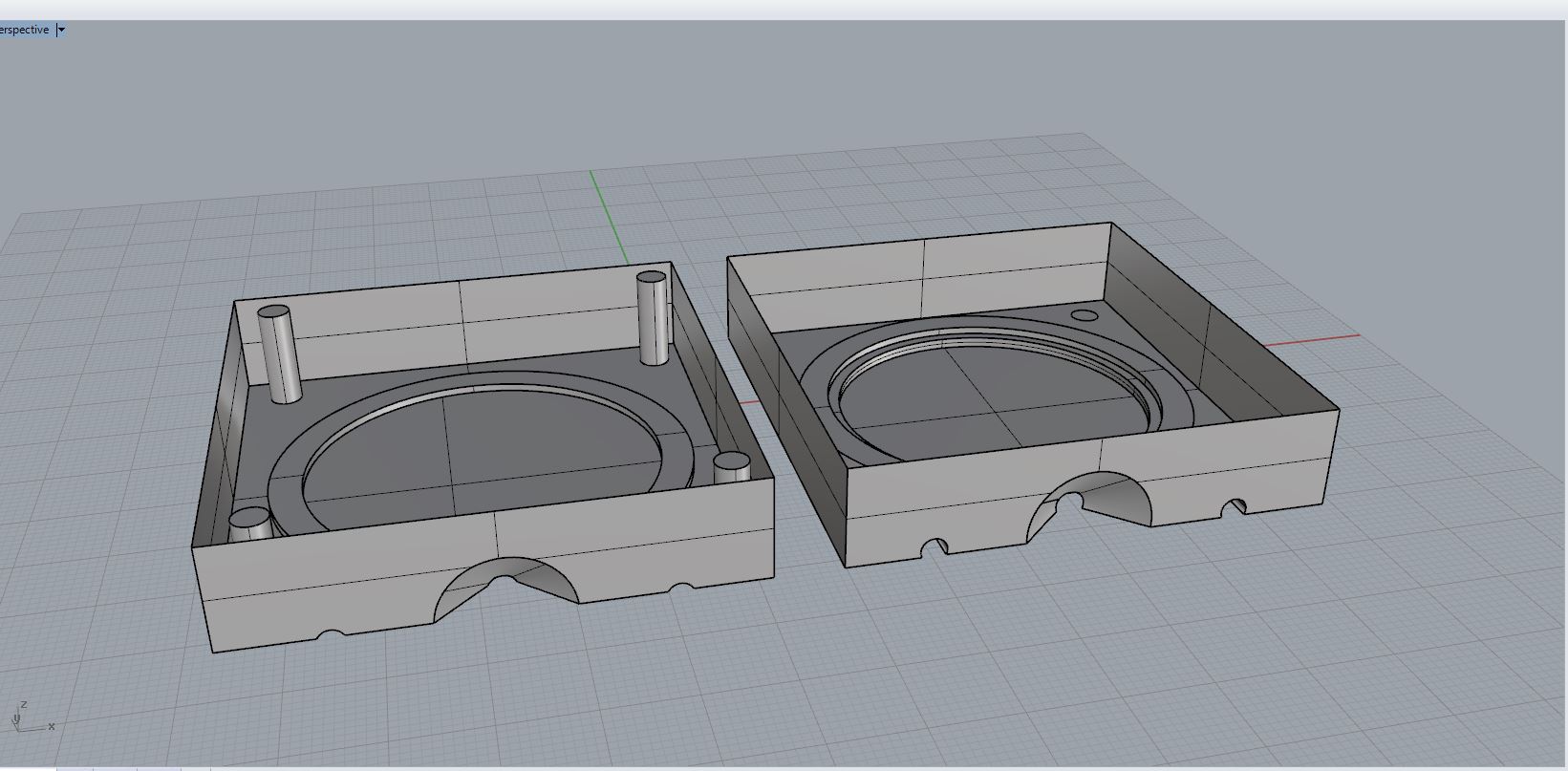

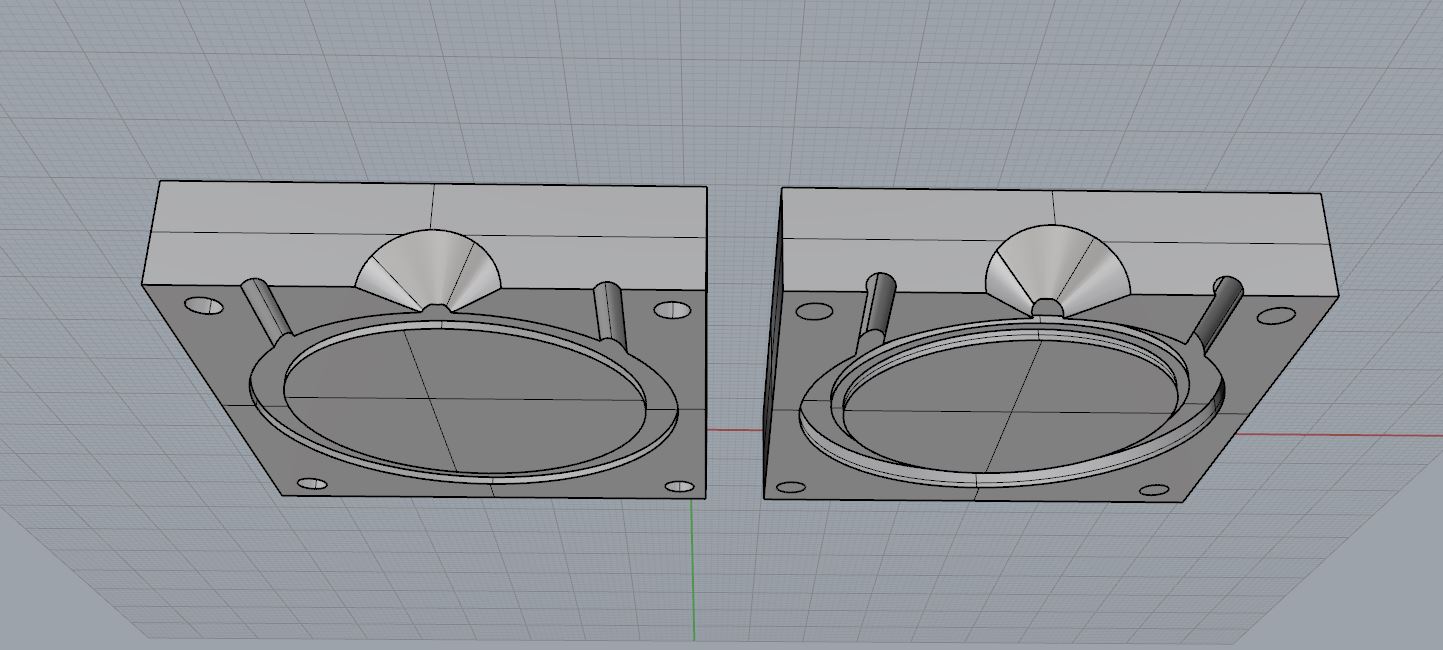

My CAD model made in Rhino

-

The main reason I used Rhino as a software for this is because its easy to split surfaces

-

- I used the Roland MDX 40A to mill out the wax. The wax block I fastened with double sided tape. Research suggested that one should use double sided tape and a glue gun to glue the sides of the wax to the bed but this was not necessary.

- I used the Roland software that the machine comes with which was the VPannel for operating the machine and MODELA 4 for making the paths for the milling process.

- The MODELA PLAYER 4 makes 3 different paths to machine. First Surfacing the wax which makes the wax level ,Second a rough path is milled which slowly removes the main material from the positive. Then the last or third process Finishing mills out the final more detailed profiles of the profile.

-

- I used a 3mm square bit to mill out the profiles. For more rounded edges a round bit would be recommended. Below you can see the end result of the milling process.

- It is advised to keep the wax that is left over from the milling process for melting down for a new wax block.

- Because of were the Milling was done and were I zeroed the machine, the walls of my mould were milled away so I built a Perspex box to seal and cast the mould. It is advised to design walls to create pockets for the OOMOO Resin.

- I used OOMOO 25 to make my mould, it is advised to read the spec sheet before opening the container and begin the mixing process. The OOMOO was mixed 1:1 so one part of A to one Part of B. I did read all the other info on the SMOOTH-ON website and it was recommended that first pour part B into the cup before A to ensure easily but thorough mixing.

-

OOMOO is poured. It is advised that the OOMOO is poured evenly and slowly on one area to ensure an even bubble less casting process.

- Once it is cured after 75 minutes, I left it in there for 2 hours just to make sure.

My first ever mould. I think it came out nicely, just sum minor trimming had to be done at the pouring hole.

My first ever mould. I think it came out nicely, just sum minor trimming had to be done at the pouring hole.

-

-

Just to double check if my design was done correctly

-

-

After the trimming was done.

-

- I used Q20 as a release agent, it works pretty well.

- The first cast I used PMC-121/30 Wet to cast my positive. It is mixed to 1:1 Ratio and takes 16 Hours to cure, I left it overnight +- 20 Hours.

- The wait.

-

- Finally it set and I de moulded it, works pretty well and my Record player is finally fixed.

- Time for trying Smooth-Cast 305, a hard white plastic. Curing time is 30 minutes and mix ratio is also 1:! but READ THE SPEC SHEET

- Positive done, I was quite surprised of how well it casted with the detail.

what not to do.....

-

So I wanted to try and cast OOMOO into a OOMOO mould so that I could get a positive of OOMOO as it has a much better strength and durability for what I am trying to achieve

This does not work.... at all... the OOMOO mould became part of the part I was trying to cast. I did use Vaseline (and allot of it) as a release agent.

Downloads